Starting System of vehicle and

starter motor

Requirements of

Starting System

•

An internal combustion engine

requires the following criteria in order to start and continue running.

•

Combustible mixture.

•

Compression stroke.

•

A form of ignition.

•

The minimum starting speed (about 100

rev/min).

•

Long service life and maintenance

free.

•

Continuous readiness to operate.

•

Robust, such as to withstand starting forces,

•

Vibration, corrosion and temperature

cycles.

•

Lowest possible size and weight

•

In order to produce the first three

of requirements, the minimum starting speed must be achieved. This is where the

electric starter comes in.

The ability to reach this

minimum speed is again dependent on a number of factors.

•

Rated voltage of the starting system.

•

Lowest possible temperature at which it must

still be possible to start the engine. This is known as the starting limit

temperature.

•

Engine cranking resistance. In other words the

torque required to crank the engine at its starting limit temperature

(including the initial stalled torque).

•

Battery characteristics.

•

Voltage drop between the battery and the

starter.

•

Starter-to-ring gear ratio.

•

Characteristics of the starter.

•

Minimum cranking speed of the engine at the

starting limit temperature.

TYPES OF STARTER MOTOR

•

Inertia

Starter

•

Pre-Engaged

Starter

•

Permanent

Magnet Starter

•

Heavy

Vehicle Starter

•

Integrated

Starter

•

Reduction

Gear Starter

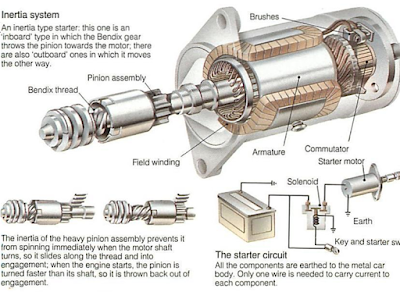

Inertia Starter Motor

Bendix Drive ( Inertia

Drive)

Working Principle of

Bendix Drive:

•

With the Bendix self-engaging pinion

drive, the armature shaft spins and the drive pinion stands still while

the threaded sleeve spins inside the pinion. As the sleeve spins, the pinion

slides out and meshes with the ring gear. As soon as the pinion reaches its

stop, the turning sleeve causes the pinion to turn with it to crank the engine.

•

In detail 1, the armature shaft and

pinion sleeve begin to spin. The stationary pinion is sliding to the left. In

detail 2, the sliding action is stopped, and the pinion begins to turn and

crank the engine. When the engine starts, detail 3, the pinion is spinning

faster than the threaded pinion sleeve. This spins the pinion back out of mesh

with the ring gear

Pre-Engaged Drives

•

Pre-engaged starters are fitted to

the majority of vehicles in use today. They provide a positive engagement with

the ring gear, as full power is not applied until the pinion is fully in mesh.

They prevent premature ejection as the pinion is held into mesh by the action

of a solenoid.

•

A one-way clutch is incorporated into

the pinion to prevent the starter motor being driven by the engine.

•

A Pre-engage starter motor is very

similar to an inertia starter however instead of using inertia to throw the

pinion out a small solenoid is used to engage the pinion before the armature

turns the engine over. A primary circuit throws the pinion out, once the

pinion has been thrown out power is feed to a second circuit to hold the pinion

in place as the armature turns

0 Comments